Operating System:Versatile, compatible with multiple industrial protocols

Processing Speed:Up to 1 MHz for rapid data processing

Memory Capacity:256 KB of program memory, expandable up to 1 MB

Power Supply:12-24V DC, wide input voltage range for stable operation

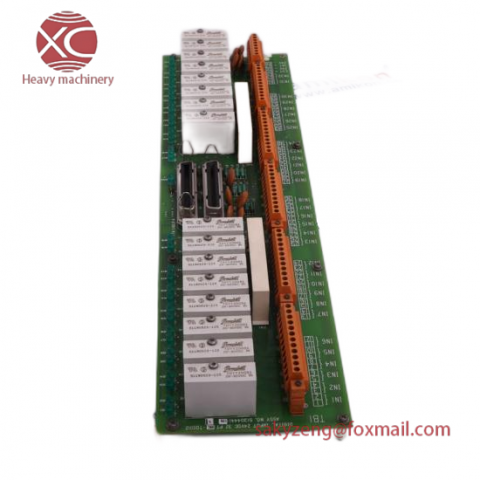

Input/Output Channels:24 I/Os, configurable for diverse applications

Communication Interface:RS-485, CANopen, and Ethernet for seamless integration

Environment Resistance:IP65/IP67 enclosure for harsh industrial environments

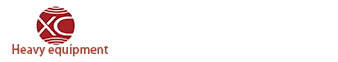

Engineered for precision and reliability, the Honeywell 51197066-200 Control PLC Module is an essential component for modern industrial automation. Its robust design ensures stable operation under demanding conditions, making it ideal for applications in textile, printing, rubber and plastics, woodworking, and other manufacturing sectors.

Featuring a quick commissioning process through application macros and panel assistants, this module simplifies setup and reduces downtime. It includes a safe torque off function (SIL3), enhancing safety standards in critical operations.

With sensorless vector control for both induction and permanent magnet motors up to 599 Hz, the Honeywell 51197066-200 optimizes performance across a wide range of speeds. The built-in braking chopper ensures smooth transitions between active and passive states, preventing overshoot and improving overall system stability.

The modular design allows for easy customization and expansion, making it adaptable to evolving industrial needs. All variants are equipped with coated boards for enhanced durability in harsh environments, ensuring longevity and reduced maintenance requirements.

For applications requiring additional environmental resilience, Honeywell offers a variant specifically designed for harsh conditions and solar pump drives, providing extended reliability in outdoor or remote locations. The Honeywell 51197066-200 is not just a tool; it’s a trusted partner in driving efficiency and productivity in industrial automation.

There are no reviews yet.