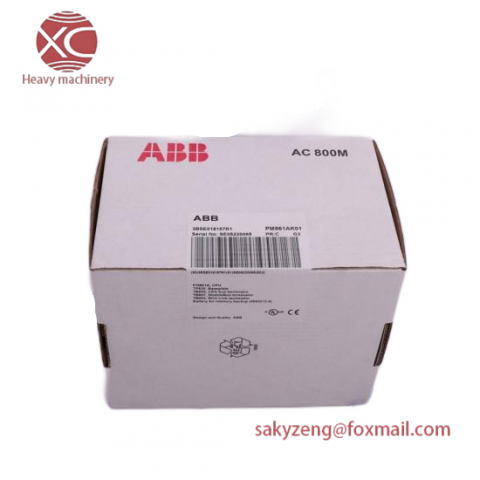

Brand:ABB

Model:IGM K5

Sub-Model:Welding Robot Teach Pendant

Module Category:Industrial Automation Control

Interface Type:Teach Pendant

Operating Frequency:Up to 50 Hz

Operating Voltage:230 V AC

Current Consumption:Less than 1 A

Protection Class:IP65

Control Signals:16 digital inputs, 16 digital outputs

Communications Protocol:Modbus/TCP, Ethernet

Weight:Approximately 0.5 kg

The ABB IGM K5 Welding Robot Teach Pendant is engineered to elevate precision and productivity in industrial welding processes. This compact yet powerful control module is equipped with a high-resolution, intuitive 5-inch touchscreen, offering an ergonomic interface that enhances user interaction.

Featuring 12 programmable function keys, users can customize their workflow, increasing efficiency and reducing errors during welding operations. The inclusion of multiple language support ensures accessibility across diverse work environments, promoting seamless collaboration among international teams.

With advanced communication capabilities via EtherCAT protocol, this pendant seamlessly integrates with ABB’s Robot Controller, enabling real-time data exchange for enhanced process monitoring and control. The extended operating range, up to 10 meters via cable, provides flexibility in setup and operation, accommodating various workspace configurations.

Crafted from durable materials, the ABB IGM K5 Welding Robot Teach Pendant is built to withstand demanding industrial conditions. Its robust design ensures reliability and longevity, minimizing downtime and maintenance requirements.

This product exemplifies ABB’s commitment to innovation and excellence in automation solutions. By leveraging the ABB IGM K5 Welding Robot Teach Pendant, manufacturers can achieve higher quality outputs, increased throughput, and improved safety standards in their welding operations.

There are no reviews yet.